Very often the thing that stumps us as home sourdough bakers, in our quest to make brilliant bread, is our ambient temperature. The bacteria harnessed in sourdough breads and starters work well at warm temperatures and if we keep our living space cool, we”ll often struggle.

I have previously written an article How To Keep Your Sourdough Starter Warm which gives lots of ideas as to how to cosset a starter. Sometimes, despite trying all the easier methods (like an airing cupboard or a warm water bath) you aren’t able to get the results you need. This is where a proofing box can be heaven-sent. As well as giving you stable warmth to make creating a starter easier, it can also help you be in charge of your baking schedule – making sure you don’t have to get up at 3am because your dough is ready for the oven!

You can buy professional proofing boxes, but they are expensive and take up extra room in your kitchen. It is relatively easy to make your own, DIY, proofing box.

The simplest, non-thermostat, type is described in my earlier article linked above. They are of some help, but I have found a temperature-controlled set-up to be far more useful. And it’s not difficult, once you understand the electronics. I am a home-cook, and know next-to-nothing about electronics, but I’ve managed to get a grip on the ‘how’. I will describe it here in the simplest non-electrician language that I can. Please accept my apologies if you know what I’m talking about already. Please linger if you don’t – it’ll be worth it!

Here’s how to make a DIY proofing box with temperature control, to help you with achieving and maintaining a desired temperature whilst you are creating a sourdough starter or proofing sourdough bread dough.

The bits you’ll need:

- A small insulated space

- An AC/DC transformer

- A heating element

- A thermostatic controller (this has two parts, a controller and a probe)

- A power cord and a plug, plus some DC cabling and connectors

Considerations/Options for the above:

Small insulated space

Options for this include a polystyrene box, or something along these lines constructed with foam packaging, a microwave (please be careful – these are not safe to dismantle), a toaster oven or even a standard oven. It need not still be working, but it does need to shut reasonably well.

AC/DC transformer

The AC/DC transformer you choose must convert to the DC appropriate to the thermostat and heating element you have chosen. Generally speaking in Europe this is going to mean 220 Volts AC to 12 Volts DC.

Heating element

This needs to be an appropriate output for the insulated space you want to heat. A 40 or 50-Watt heating element will be good for an average size microwave-sized space during northern-hemisphere spring and autumn temperatures. Increase the size of the space, or lower your ambient temperature and you’ll probably need a more powerful element.

Thermostatic controller

This is an LCD display showing the temperature inside your proofing box and allowing you to set it to what you desire. The controller then switches the heating element on and off automatically in order to maintain that temperature. The best way to explain how to choose a thermostatic controller is by showing an example of the components we used.

An example of the components we used:

Our heating element’s power rating is 48 Watts and it runs on a 12 Volt power supply. Our thermostatic controller runs on a 12 Volt power supply and can work using a current of up to 10 Amps. Also our transformer can supply up to 10 Amps at 12 Volts.

The formula:

Here it is in plain English so you can just match the numbers up and do the sums.

Power (Watts) = Current (Amps) * Potential (Volts)

For our heating element:

Potential (Volts) = 12 Volts

Power (Watts) = 48 Watts

Therefore, substituting the values we have into the equation:

48 = Current (Amps) * 12

Current (Amps) = 48 / 12 = 4 Amps

Since our thermostatic controller can handle up to 10 Amps we are safe! And our transformer can supply up to 10 Amps also so that’s sufficient. These are the figures you’ll need to look at on the component specifications – then insert them into the equation above.

So what should I do?

- Choose a heating element with an appropriate power rating as described above.

- Choose an AC/DC transformer with an appropriate input voltage for your geographical region and an appropriate output volage for your heating element.

- Choose a thermostatic controller with the same operating voltage as the first two components and then put the power rating in Watts plus the operating voltage of the heating element into the equation above. Provided the optimum current (Amps) of the heating element does not exceed the maximum current of the thermostatic controller or the AC/DC transformer then you are all set!

- Build it – there is an example of the circuit and a picture of our set up below. It is helpful to use DC cabling and connectors between components to avoid things short-circuiting.

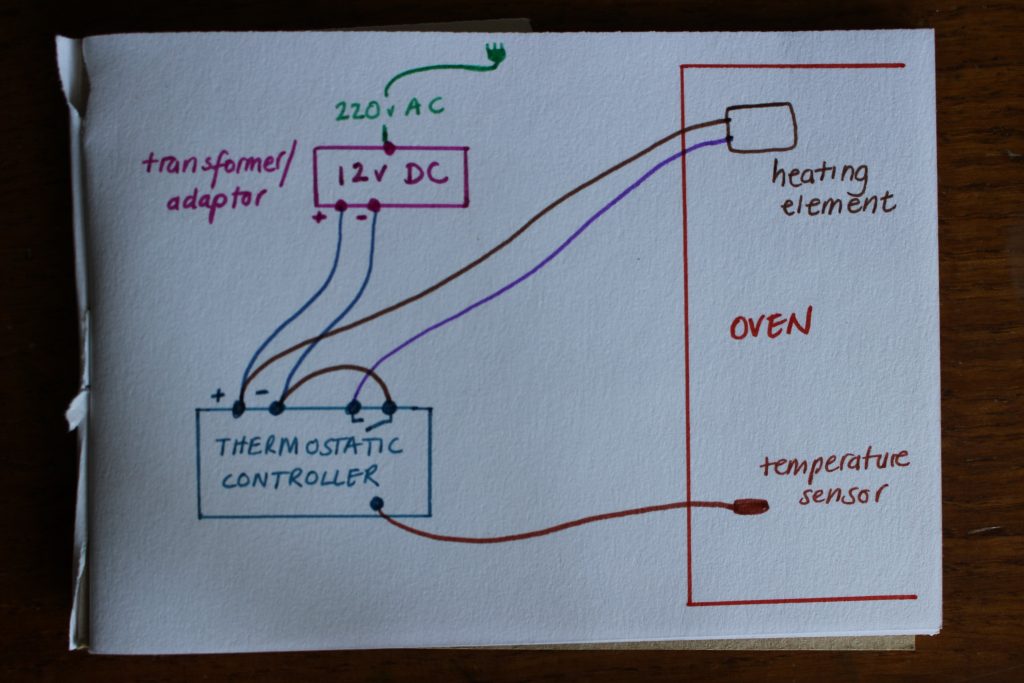

Here’s a diagram of the circuit:

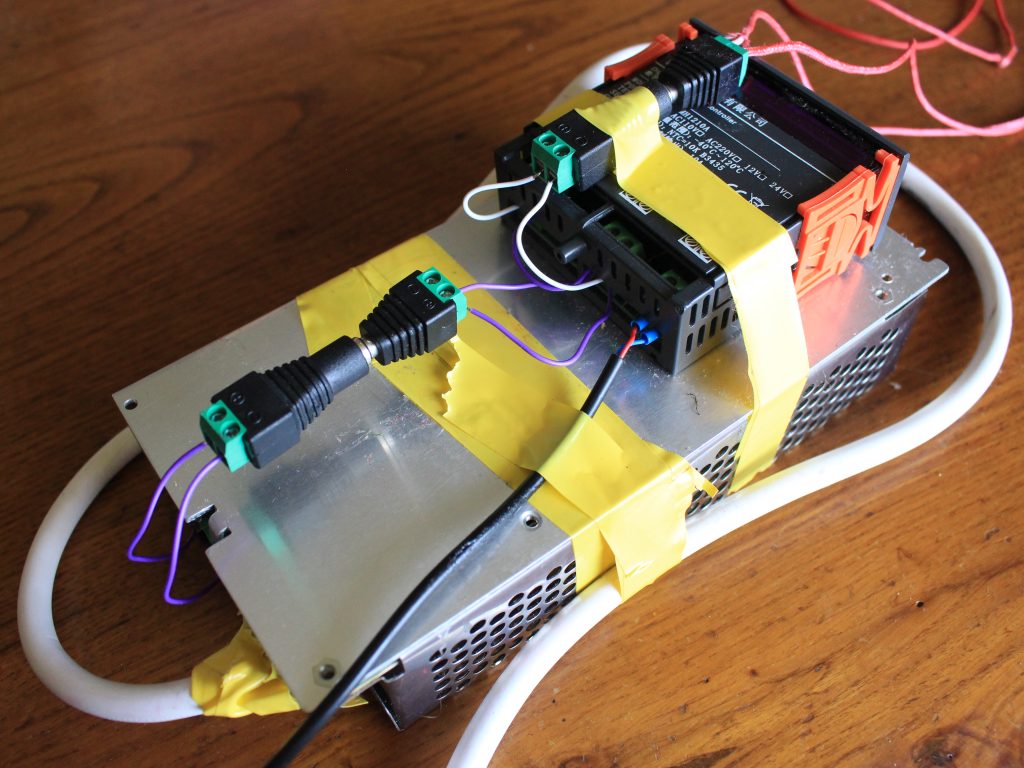

Here’s what our set up looks like:

Here are the parts we used, from Amazon – the products may not be available from the same sellers in your part of the world (or may not be available any more in these listings), but you can use the specifications here to familiarise yourself with what you need.

Heating element

Temperature controller

Power supply

Power connectors

https://www.amazon.co.uk/WOWLED-Connector-Terminal-Male-Adapter-Security/dp/B019RHFUJ2

Cabling

https://www.amazon.co.uk/Black-1mm-16Amp-Automotive-Marine/dp/B01819HUOA

Two quick addendums from years of use:

1/ The power supply has two sets of outputs and we’re currently using a large oven as our proofing space! Therefore in winter I have set one of the power supply outputs permanently to power a 50W heater and the other to power the thermostatic controller which powers another heater. The first heater (on all the time) can usually keep the oven in the low 20s degrees C while the second tops it up to whatever we set it to (ie 25C or 28C).

2/ Heat-shrinkable plastic tubes are available – they protect the joins between cables and components much better than electrical tape does. Here’s a photo of these being used on our set up:

Want some help with your sourdough starter? Check out my $5 course at The Fermentation School 10 Tips for Creating and Maintaining a Sourdough Starter!

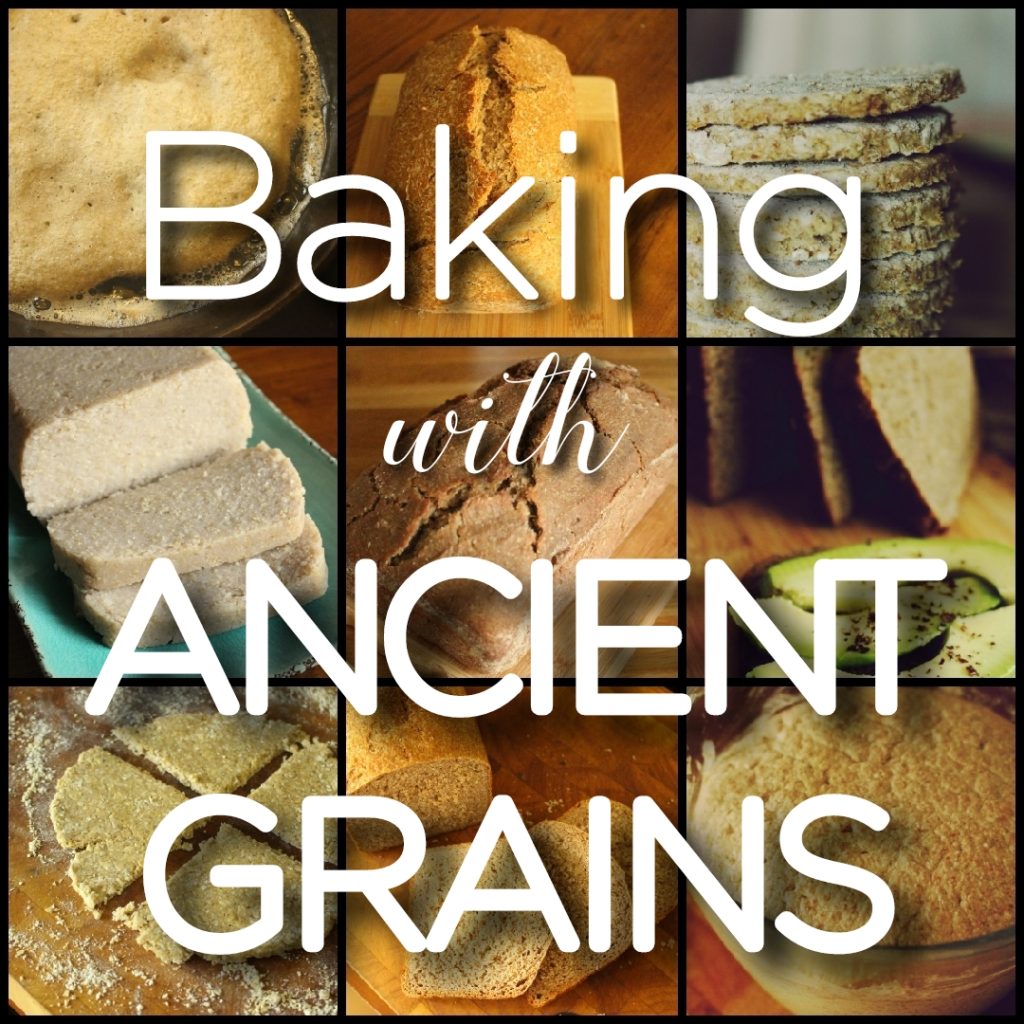

Bring ancient grain baking into your kitchen!

Download my free 30-page guide with five healthy and tasty 100% ancient grains recipes.

[…] To make this loaf – both to raise the leaven and proof the bread, you’ll need a warm place (warmer than a ‘standard’ sourdough set up). Lactobacillus grow best at 28C/84.5F though I have successfully created the leaven at temperatures between 22C/71.5F and 28C/84.5F. In some environments, the bread might need some help – an airing cupboard or warm room. If you need it, click here to have me guide you through how to create a DIY proofing box. […]